Continuous Rubber

JCC

Description

Anti-slip, non-toxic, ecological RECYCLED AND RECYCLABLE quality rubber. Continuous rubber pavements made of high quality materials according to the EN-1177 European security standard.

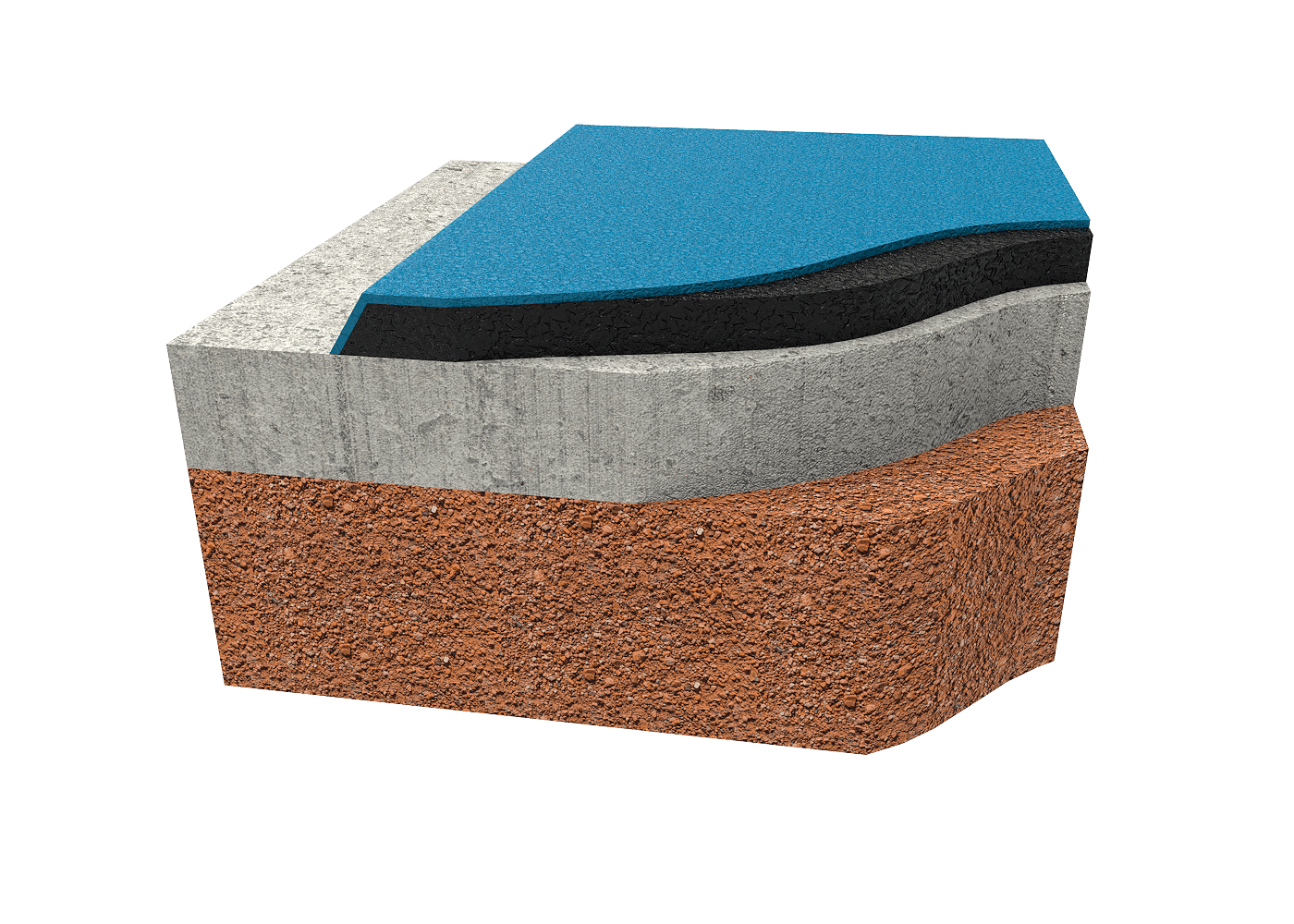

Installation

"In situ" rubber pavement is directly installed on site. First, apply a layer of SBR and polyurethane granules. Then, apply a top layer of EPDM granules of different colours. The absence of lines and the great variety of colours allow to make customised designs. The use of continuous rubber allows the creation of several layers in the same area.

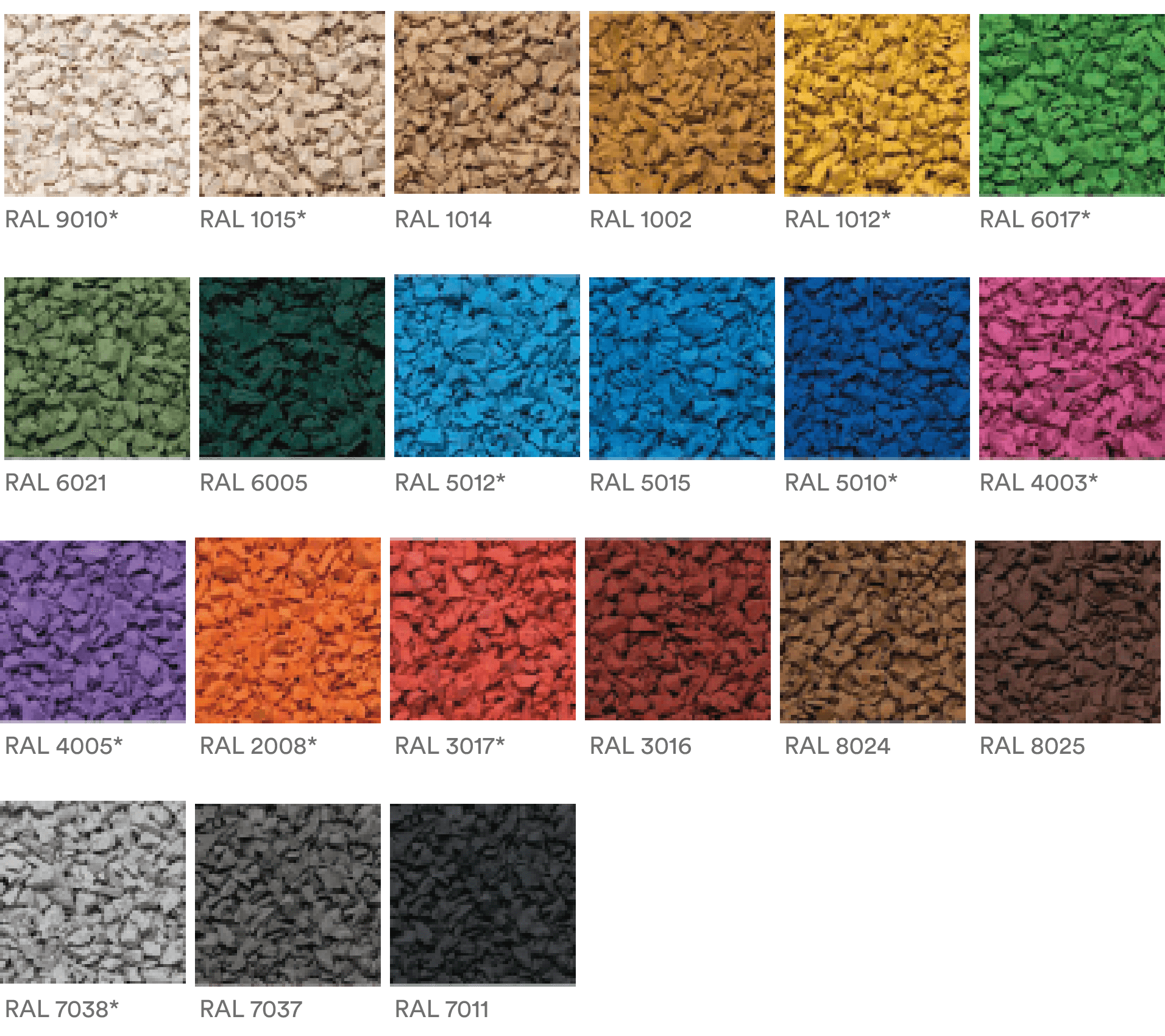

EPDM Granules produced by mixing vulcanised EPDM rubber, natural mineral fillers, paraffinic mineral oils, dyes, processing and vulcanisation auxiliary agents, and anti-aging agents. Great variety of colours.

SBR 2-7mm rubber granules mechanically produced from tire peeling. Free of impurities and metallic particles. Colour: black.

Use

SBR + EPDM: ideal for playground areas, schools, garderies, sports areas, nursing homes and any other area where people can fall.

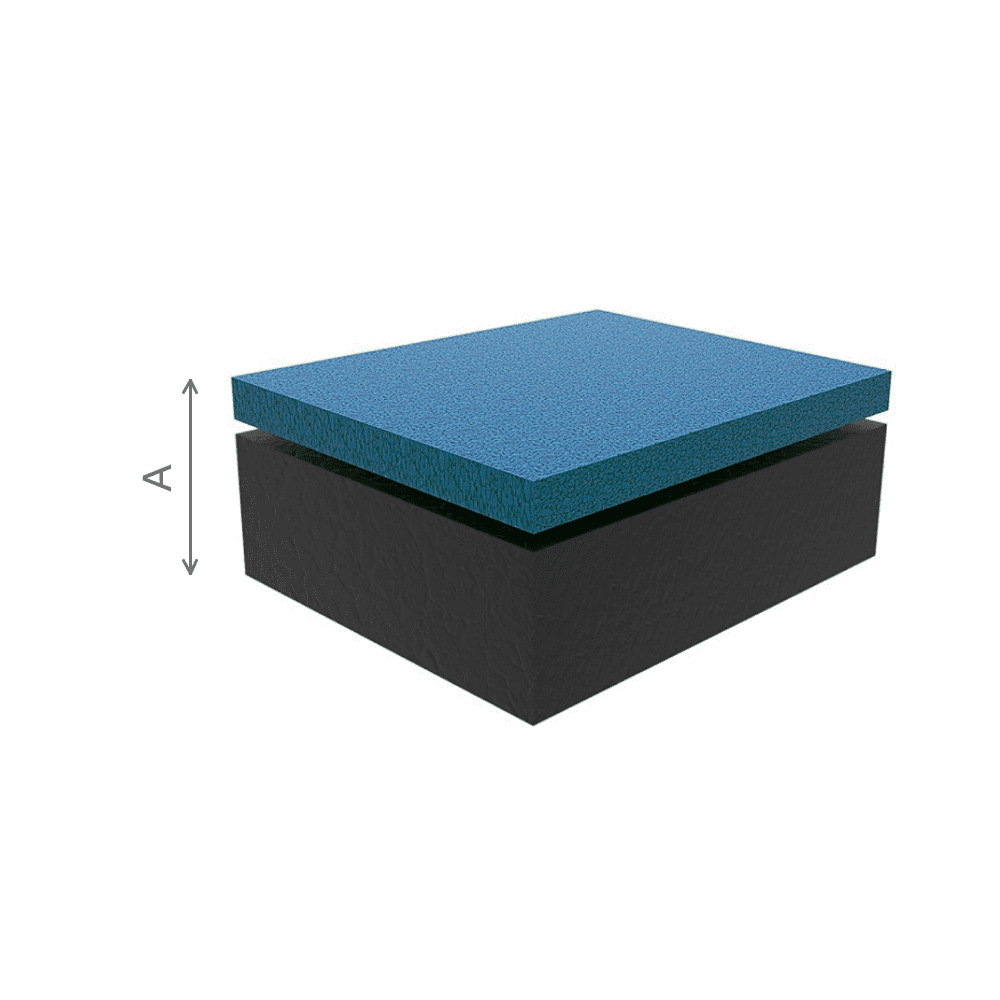

Thickness: standard thicknesses from 20mm to 80mm, thus allowing the creation of several layers in the same area.

Discolouration can happen with time without affecting the characteristics of the tile.

(*) Colours needing aliphatic resin.

Maintenance

- Routine maintenance: cleanings consists of sweeping the area and, when necessary, a thorough pressure washing at the indicated tempretaure as well as a garbage collection. It is recommended to carry out this maintenance once a month or more in case of intensive use.

- Corrective maintenance: consists of repairingloose, defective or damaged parts as a result of their use in order to maintain a proper security level. In case of depigmentation, a resin primer must be applied to protect the ground. An annual examination of the coating absorption levels of each equipment installed on the area is recommended to ensure they comply with the EN-1177 standard.

Note: colours are approximations of the original colours.

See more…